We are an independent research & design lab pairing creativity with rigor to bring new solutions in renewable energy and robotics to market.

About us

Similar to an accelerator/incubator, but with internally developed ideas, we nurture projects through the initial R&D phase, to forming internal entities, and eventually fundraising and spinning out into independently operating companies.

Over the past 10 years, we’ve raised over $70M in research and design contracts, amassed $100M in follow-on capital and spun-out 12 companies.

Currently, we help government agencies and Fortune 500 companies understand energy infrastructure and build transformational technologies that bring us closer to 100% decarbonization.

careers

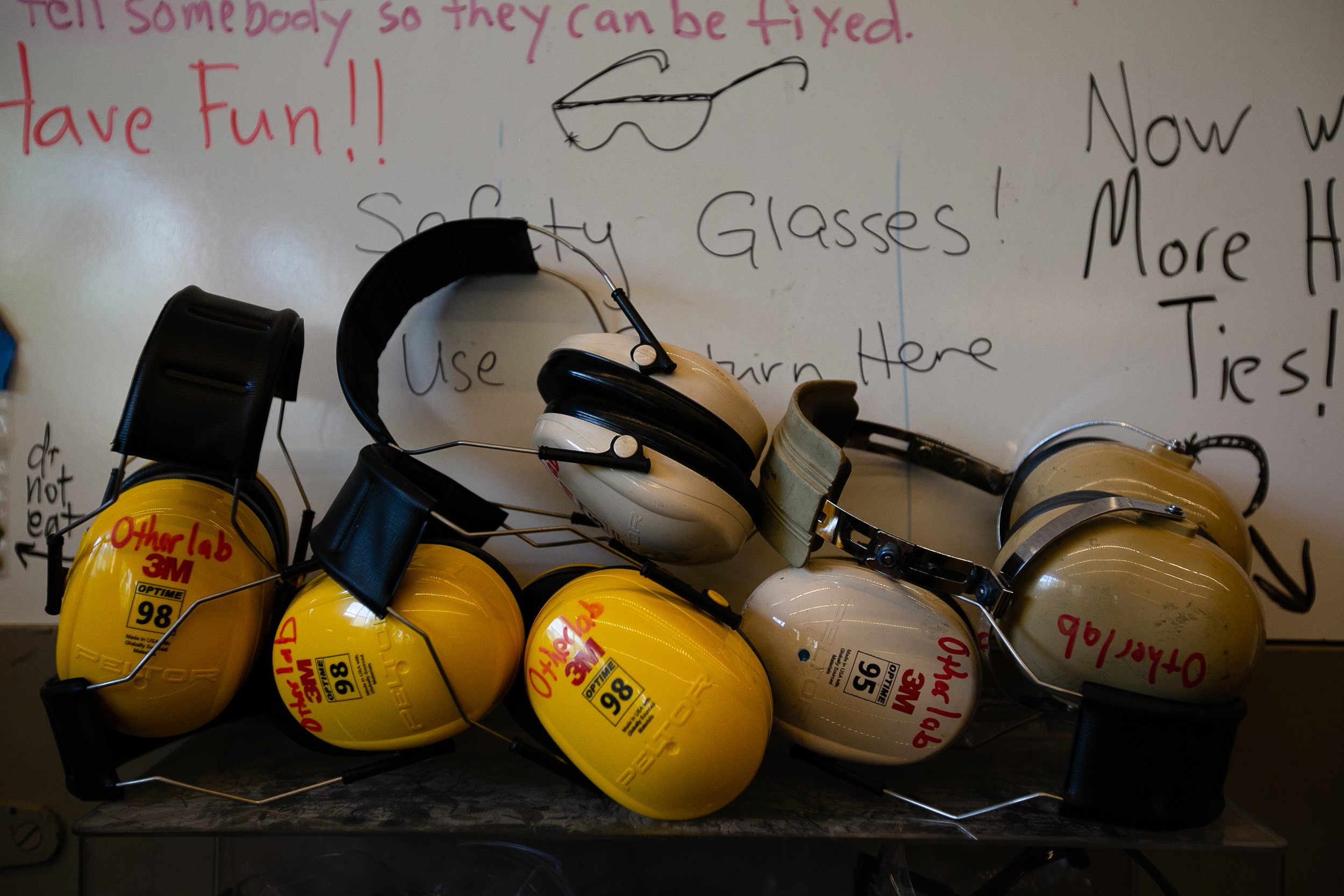

Otherlab is a group of inventors, engineers, scientists, and business people striving to impact the energy, robotics, manufacturing, and education sectors. Our research lab is a place where ideas are seeded, grow, and develop into startups. We are always looking for talented and passionate people to join our team.

Otherlab’s Diversity Statement

Otherlab’s vision is to create new technologies that change the way energy is generated and consumed while building successful companies that solve global problems through collaboration and innovation. Given that underserved and marginalized communities are disproportionately affected by the negative impacts of climate change, developing renewable energy and decarbonizing technologies is key to a cleaner, safer, and more equitable future for all.

Inventing new products and energy technologies that can scale to impact a wide range of communities requires brilliant minds that come from all outlooks and backgrounds. Otherlab recognizes that more significant innovation is achieved when diverse perspectives are heard. We strive to create a positive and inclusive environment of collaboration and creativity where all people can contribute and feel a sense of belonging.

Team

Saul Griffith

Founder, Chief Scientist

James McBride

Co-founder, CTO

MAGDA JANSONE

VP Finance & Operations

Pete Lynn

Senior Engineer

Margaret Long

Shop Manager

Jake Lacore

Senior Technician

Patti Lord

Program Lead

Conor O’Brien

Senior Mechanical Engineer

SHEENA MILLER

Operations Manager

current projects

Focused on energy, automation, and robotics in service of decarbonization.

solar-powered electric scooter

At Otherlab, we designed the Lightfoot scooter and brought it to market in November 2024 as part of our commitment to reducing transportation-related carbon emissions, which account for nearly 30% of U.S. emissions. Lightfoot offers a sustainable alternative to traditional vehicles by reimagining personal transportation with an emphasis on efficiency and practicality, making short trips cleaner and easier.

With solar charging, regenerative braking, and a 37-mile range, Lightfoot provides a zero-emission solution for everyday use. By integrating modern technology, it offers a more efficient way to navigate our communities. As we transition to a decarbonized economy, Lightfoot exemplifies how electrified solutions can deliver both environmental and practical benefits.

Distributed sterilization of Medical waste

With funding from the Centers for Disease Control and Prevention (CDC) and in partnership with the University of Nebraska Medical Center, Otherlab is enhancing infection control in healthcare settings. Our focus with the SHIP-C initiative is on transforming the management of regulated medical waste.

Currently, regulated medical waste is transported throughout healthcare facilities and consolidated before being taken long distances for incineration. In contrast, Otherlab is developing innovative solutions that allow for the final disposition of waste at its source—specifically in procedure, operating, and labor & delivery rooms. This approach aims to transition regulated medical waste into municipal waste before it exits the room, streamlining the waste management process and improving overall safety.

Battery Integrated Appliances

At battery capital costs of $100/kWh and a conservative lifetime of 2000 cycles, the cost of storage is 5c/kWh. In the U.S., where the total average cost of residential retail electricity averages 13.8c/kWh and the cost of transmission and distribution alone can be 5-12c/kWh, local generation and storage have the potential to undercut the cost of grid-supplied electricity, with significant additional resiliency benefits. Major R&D programs are driving soft costs out of residential solar, but as evidenced above, the market is on track to retain significant soft costs associated with battery storage.

To this end, Otherlab is developing technology to push battery storage from centralized installations in the home out to the points of load. In this distributed model of energy storage, appliances are equipped with onboard batteries and manage their demands on the home and utility grid.

Structurally Optimized Solar:

a BIPV Project

Corrugated sheets are widely known to provide significant material and weight savings compared to a flat plate of equivalent stiffness. The most ubiquitous example is corrugated cardboard- the dominant, lowest weight/cost packaging material, of which 200 billion square meters are produced every year. Otherlab is working to exploit these coupled benefits to build a structurally optimized solar photovoltaic product at a lower possible weight and cost per watt installed. We have found that equivalent stiffness can be achieved using 10 times fewer structural materials than a conventional panel, and simultaneously solar production can be increased by 5-10% over the year, principally during the important off-peak hours when demand typically outstrips supply. This work will express how roofing and solar can be combined into a single product and will significantly reduce the soft costs of installation, bringing residential solar to homeowners in a much broader economic background.

ISTARI CARECube: Infectious disease isolation units

A revolutionary portable negative pressure containment patient care system. The ISTARI Carecube family enhances safety, improves care quality, and cuts costs for managing infectious diseases by minimizing the need for personal protective equipment (PPE). This is achieved by wrapping PPE around the patient, reducing equipment processing and extensive IPC training burden.

Addressing common infrastructure challenges, ISTARI Carecube boasts transparent, flexible walls that promote patient interaction with providers and visitors. As a family of devices, ISTARI Carecubes offer versatile use cases ranging from patient transport to extended critical care environments. Devices are designed to be manufactured at scale in the U.S.

Developed in collaboration with the University of Nebraska Medical Center and supported by contracts with the Center for Disease Control (CDC), National Science Foundation (NSF), and a generous donation from Toyota Research Institute. ISTARI Carecube is a cutting-edge solution in portable patient care.

Isothermal Compressor

Isothermal compression saves 40% - 50% of energy compared to standard adiabatic compression. We’re applying Otherlab IP on polymer membrane heat exchangers and compliant polymer bladders to transform existing isothermal compression toward greater efficiency. The resulting innovation is focused on the $25bn global industrial compressor market and an improved efficiency target of 5%.

Ocean Farming hydrofoil

With funding support from ARPA-e’s MARINER program, Otherlab is working with Trophic and UNH to develop a modular, immensely scalable kelp farm that self-fertilizes by using currents and waves to create an upwelling of nutrient-rich seawater from the ocean’s depths.

Passive Thermo-Adaptive Textiles

Developing thermally adaptive fabrics that literally change thickness and insulation value in response to temperature change, allowing the creation of garments that passively respond to variations in temperature. The material change is a physical response, with no wires or sensors and no input from the wearer or any control system. Adaptive garments will enable the wearing of fewer layers of clothing for comfort over a broader temperature range, effectively lowering the heating and cooling requirements for buildings.

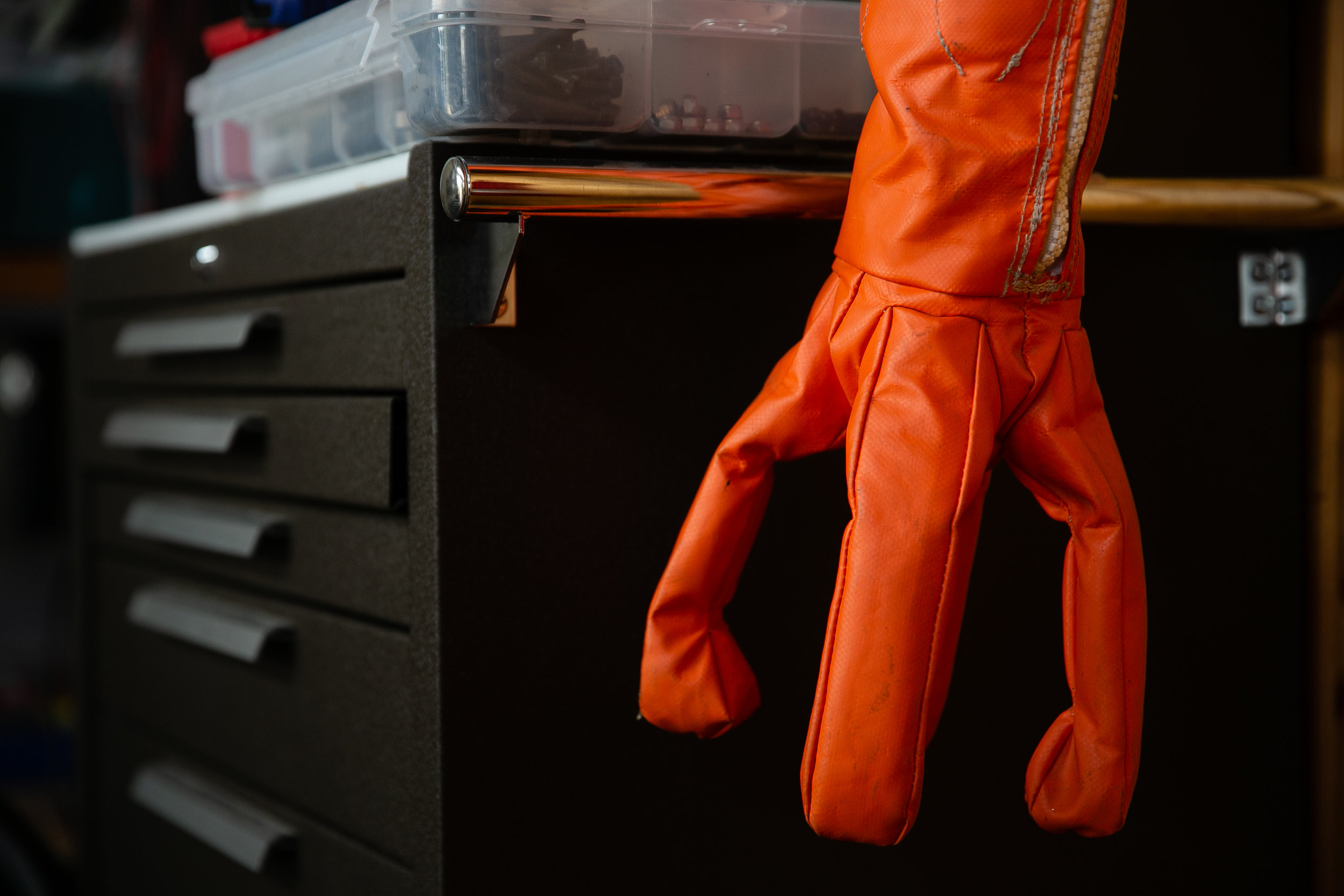

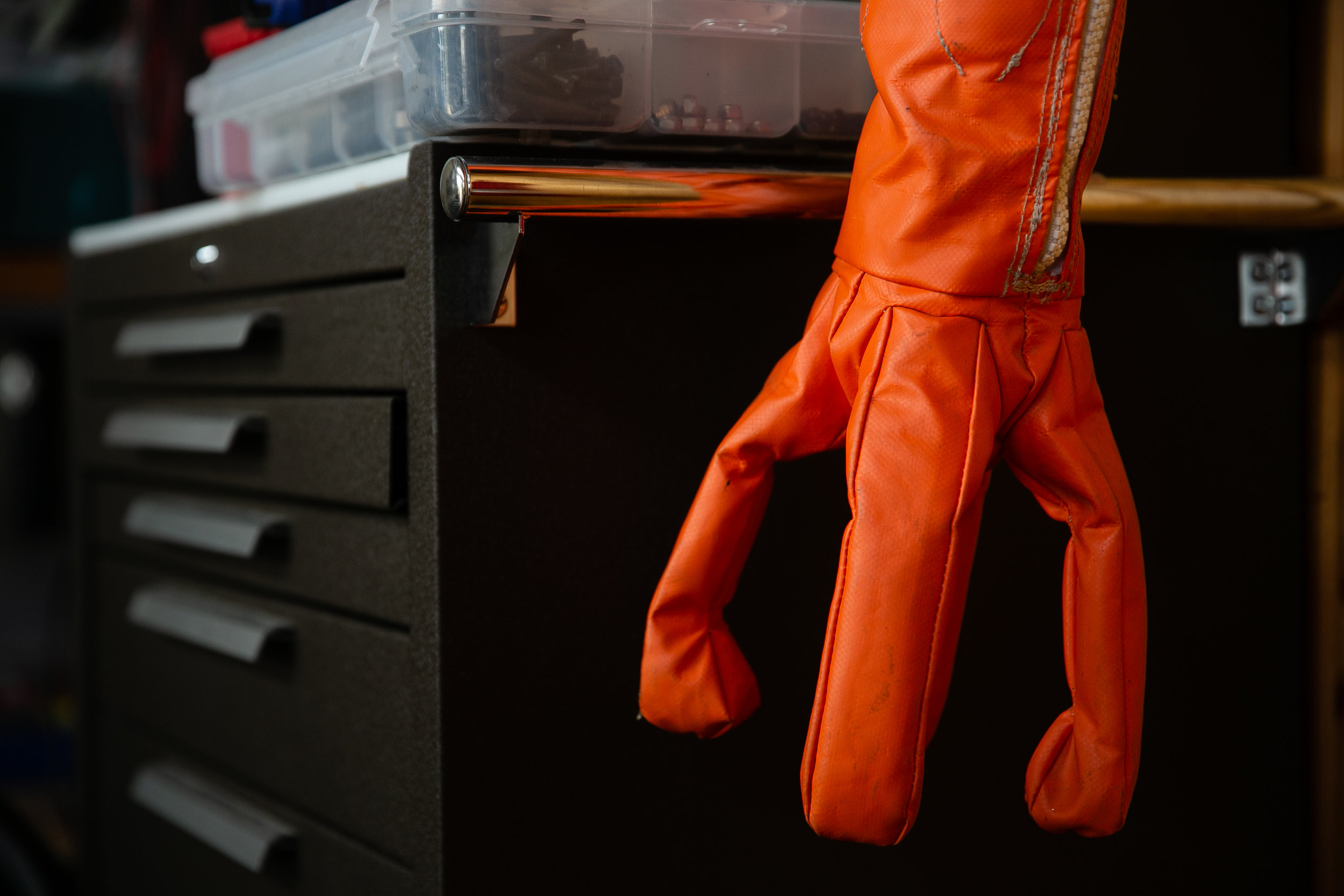

Fluidic Robotics

Creating inexpensive, mass-manufacturable robots made of textiles and plastic instead of metal. Using inflatable actuators and non-contact sensors to create smooth, sensitive motion with no moving seals. Utilizing fluid pressure to create the lightest, highest power-to-weight actuation available. Funding support from the US NAVY and NASA.

Floating Offshore Wind Power

With funding support from ARPA-e ATLANTIS Program, Otherlab is developing new architecture for wind systems based on compliant materials, energy-generating structural surfaces, and advanced control systems that overcome the need for stiff, expensive materials by actively controlling how the system interacts with the environment.

Spinoff Companies

Past Projects

Welding Robots

Internal Project

Telecopter

Partner: Industry

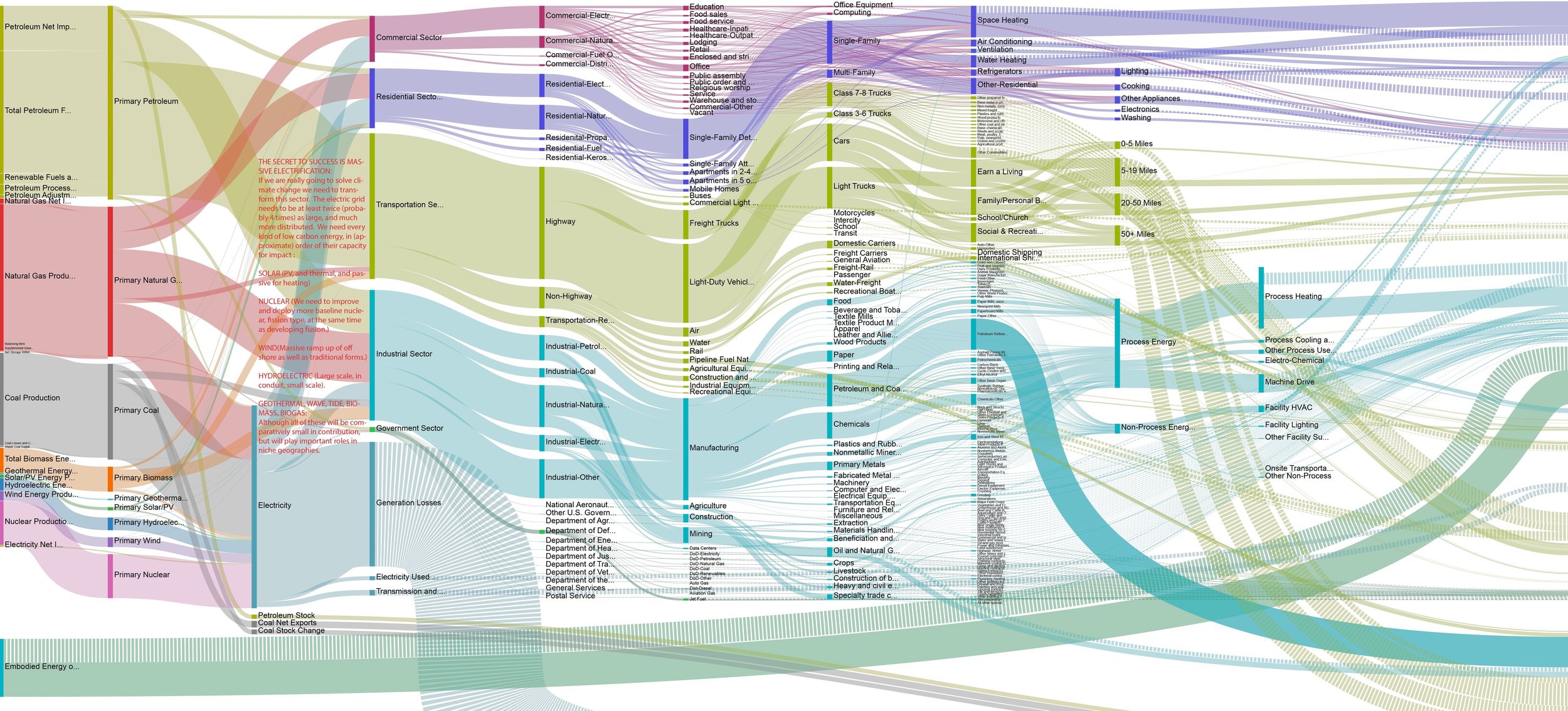

Sankey diagram of u.s. energy use

Project partners

Nasa

University of California, Berkeley

General Electric

EXELON

US Department of Energy

Massachusetts Institute of Technology

Stanford University

Yamaha MOtor Company

United States Navy

Ford Motor Company

UNIVERSITY OF NEBRASKA MEDICAL CENTER

Centers for Disease Control

CONTACT

General Inquiries info@otherlab.com

Press & Speaking Inquiries press@otherlab.com

Business & Investment Inquiries partner@otherlab.com

We live in the old Schoenstein Organ Factory building in the heart of San Francisco's Mission district.